Challenges

In seaplane accidents, victims are likely to drown following survivable crashes over water.

Drowning, the leading cause of death, is effectively prevented by life vests all aircrafts are equipped with.

I set out to understand why people were drowning and how we might increase their odds for survival.

Outcomes

Modified packaging design for life vests that can be stuck in obvious areas of the aircraft.

Increased visibility as a visual reminder to grab a vest during egress

Easier to grasp and open as fine motor control declines in cold water submersion

High-yield RF welded design to be economically competitive with standard packaging

Safer life vest storage pouch for seaplanes

Protective gear research project

After flexing my research muscle through interviews, field observation, market analysis, extensive literature review and incidence reports, the issue came into focus. In survivable seaplane incidents over water passengers often egress the plane without a life preserver. Drowning is the leading cause of death in this situation, and even in the event of a successful initial egress, drowning can occur when occupants attempt to reach stowed life preservers in the cabin rear and under seats.

"We want to find people and the chance of their survival without the life jacket is very poor,"

Bill Yearwood, regional manager of aviation for the Transportation Safety Board.

The issue becomes more complex when you take into account the range of aircraft configurations flying in any given fleet. My findings suggest that what you see in the flotation device information kiosk, the safety pamphlet, or instructional video is not always the same as what you find in your aircraft. Likely, after enduring a sudden crash, your ability to locate and retrieve a vest is severely impaired.

Research infographic

The challenge of a contextual solution

My challenge was to find a realistic solution to address this problem considerate of aircraft variety, human nature, and cost constraints.

What if we reposition the life preserver in such a way that it is intuitive to grab when exiting the craft after an emergency?

It should be easy to hold on to during egress and thus still in your possession upon surfacing.

An obvious and graspable life vest pouch is a visible disruption to the flying experience. It becomes a timely reminder of emergency procedures during an incident.

This would appeal to safety leaders in passenger transportation and commercial float operations.

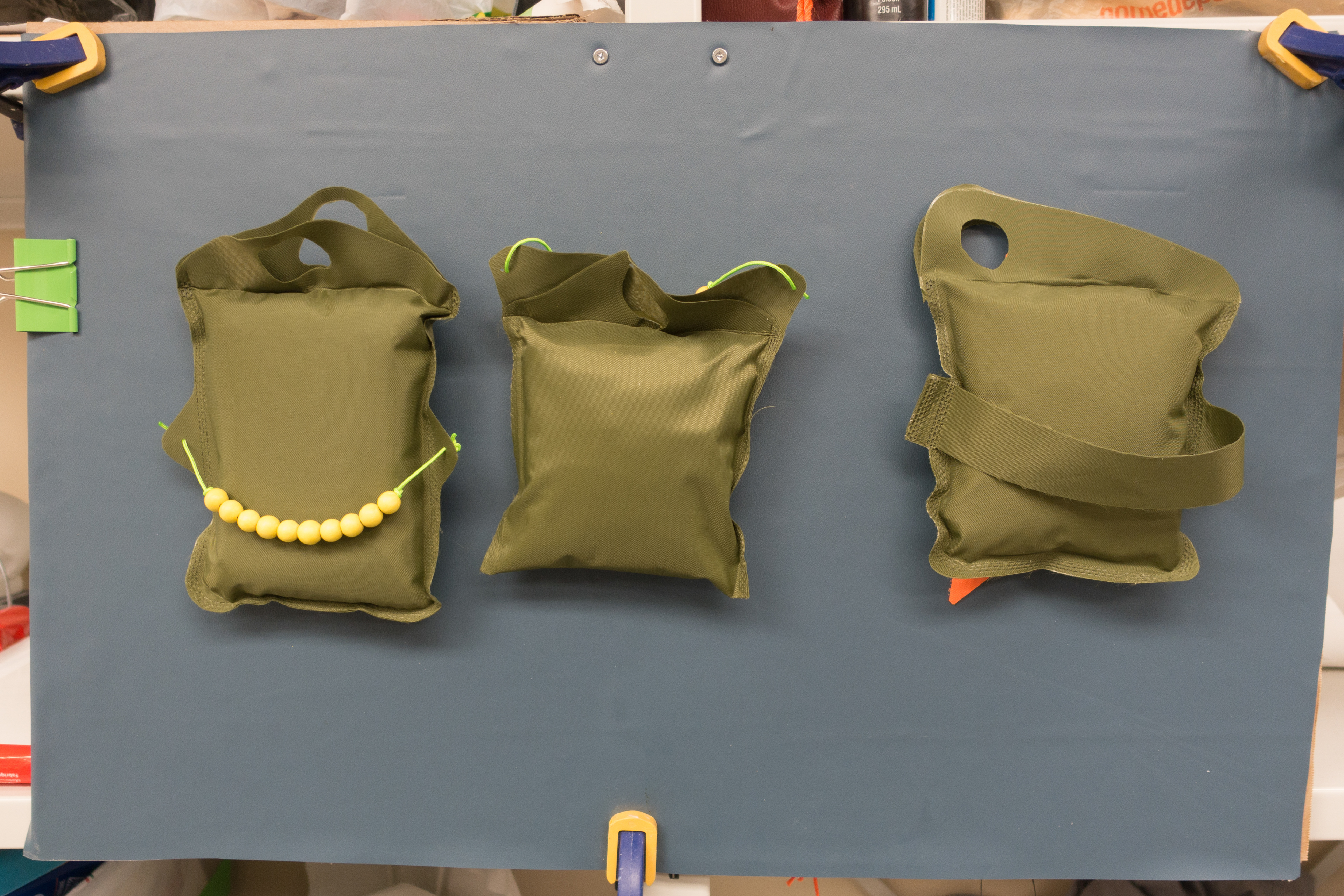

Round 1

Made using a ripstop fabric and nylon webbing for the handles.

two handles made it unclear which one to pull

ripstop is not desirable for things you intend to rip easily

Round 2

Four variations in a PU coated polyester

Pull the blue loop to remove from wall

Round 3

User testing determined the best position for peel forces, and a preference for beaded handles.

- Hi-viz coated polyester thinner weight than the previous round

- Use body material for the strap

- High yield pattern to minimize cost and waste

- Directional arrow sticks to surfaces and indicates direction of nearest exit

Can't miss it life vest storage pouch

Made to stick

This is an obvious and graspable life vest pouch for airline style life preservers, like those found on commercial seaplanes. The key difference between my design and current pouches is the positioning. Using two adhesives, the pouch containing an inflatable vest can be attached on any surface of an aircraft (e.g., headliner, door, seat, wall panel etc.) but peeled off like a turbo Post-it note during egress. To give greater control over the adhesive interface, a fluorescent coloured backing is adhered to the pouch itself. That backing is mounted to aircraft surfaces and in this case could also be an arrow pointing to the nearest exit.

Out of sight, out of mind

The bright coloured pouch ensures passengers have noticed its location throughout the flight, and can recall that even when they are disoriented. A wooden beaded handle provides excellent tactile feedback and graspability as your extremities react to frigid water.

High-yield pattern

Cost Competitive

I revised the pattern to be really simple to compete with current pouches which are light and designed for manufacturing. I optimized for high-yield and minimal waste cutting. This part of the process felt like my own undoing as I simplified and reduced the deliverable of a major project. It was the only way the solution would be realistic for commercial applications.

I used ultrasonic welding technology but in production an RF-welding form would be ideal.

Sealing urethane coated nylon with a heat press